Cold chain logistics moves millions of tons of perishable goods worldwide. A refrigerated container protects your cargo by maintaining rock-solid temperatures from start to finish. These units operate between -30°C and +30°C, covering virtually any shipping scenario.

Understanding different sizes of refrigerated containers, right temperature, and energy consumption levels is very crucial. This helps you to make the right decision and you’ll prevent spoilage while cutting costs significantly.

A 20ft refrigerated container might be perfect for your dense frozen goods. Or maybe you need something bigger for volume shipments. Either way, matching the right equipment to your specific needs is what keeps your supply chain reliable.

Understanding Refrigerated Container Dimensions and Types

Here’s what most people miss, container size affects both your freight bill and whether your cargo arrives intact. The global shipping industry built its entire infrastructure around standard sizes. Ships, trains, trucks, they all work with the same dimensions. That’s why most refrigerated cargo travels in 20-foot or 40-foot containers. These sizes plug right into transportation networks worldwide.

20ft Refrigerated Container Specifications

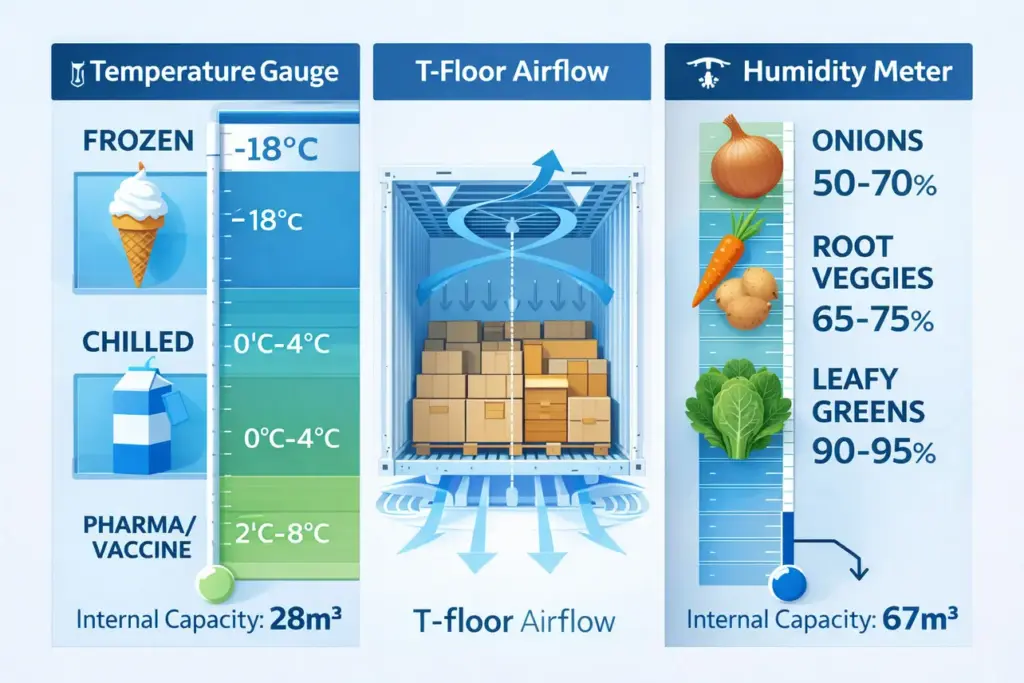

Need to ship heavy cargo or handle smaller volumes? A 20ft refrigerated container solves both problems. The outside length runs about 6.058 meters, making it easy to handle at ports and warehouses. Now, the inside is a different story. Those thick insulation walls eat up space compared to regular dry containers. You’ll get roughly 28 to 30 cubic meters to work with.

This size really shines for dense frozen products like meat, where you’ll hit the weight limit before filling the space. The 20ft refrigerated container also performs well for deliveries in tight urban areas with narrow streets and limited access.

40 Foot Refrigerated Container Specifications

The 40 foot refrigerated container dominates international shipping for good reason. More space means better economics when you’re moving large shipments. At 12.192 meters long externally, these units hold between 60 and 67 cubic meters of cargo.

Why does this matter for your bottom line? Simple. You pack more product per trip, which drives down your per-unit shipping costs. Large shipments of fruit, vegetables, and boxed foods fit perfectly. Most shipping lines now use High Cube models. The extra height improves airflow and lets you stack pallets higher.

Checking Refrigerated Container Dimensions

Before you book anything, verify the exact refrigerated container dimensions. External measurements stay standard, but internal space? That varies by manufacturer. Newer containers use thinner insulation materials without sacrificing thermal performance, giving you more usable width.

Why does this matter? Wrong dimensions mean loading delays that cost money and missed connections. Look for the red load line painted inside every container. This line shows you the maximum stacking height while maintaining airflow. Load above it and you’ll block air circulation completely.

Managing Temperature and Humidity for Freshness

Temperature control is obviously critical. But humidity and airflow? They’re just as important for keeping your products fresh during the entire journey.

Temperature Ranges for Perishables

Shipping container must keep steady temperature levels regardless of external conditions. Frozen commodities need to be stored at a temperature of -18°c or lower by manufacturers to ensure that no bacterial growth happens. Dairy products and other fresh chilled goods usually ship between 0°C and 4°C to meet safety standards.

Pharmaceuticals are another story entirely. Medicines need specific temperatures to remain effective for patients. Most vaccines must stay between 2°C and 8°C to preserve their medical properties. Shipping these? You need containers with advanced monitoring systems. Some super freezer units drop as low as -60°C for specialized research materials.

Humidity and Ventilation Control for Produce

Fresh produce continues to breathe after its harvest. It keeps giving off moisture and ethylene that speed ripening. Humidity levels can spoil crops, that’s why each crop is kept in different levels of humidity. Leafy veggies require an environment of relatively high humidity of around 90% to 95% to prevent wilting or falling off.

According to experts, root vegetables such as carrots do best at moderate levels of 65-75%. Onions like a humid level that is lower than 80% which is about 50% to 70%. The right amount of humidity prevents mold growth and sprouting. You need to modify your ventilation rates to suit your crop needs.

Specialized Storage Solutions and Loading

The best refrigeration equipment in the world won’t help if you load it poorly. Cold air needs to reach every single box in your shipment.

Solutions for Vegetable Transport

Vegetables require packaging that promotes airflow. Many shippers rely on specialized refrigerator storage containers for vegetables like ventilated crates. These allow cold air to move through the entire stack instead of just around the edges.

The right refrigerator storage containers ensure air reaches pallets in the center. Solid boxes trap heat inside and cause spoilage in the middle sections. This happens even when external temperature readings look perfect. Choose packaging that protects produce while allowing proper ventilation.

Smaller Scale Refrigerator Storage Containers

Final delivery often uses portable refrigerator storage containers instead of full refrigerated trucks. These insulated bins use ice packs rather than electricity and maintain cold temperatures for up to 48 hours. They’re cost-effective for local deliveries where running a full reefer truck doesn’t make financial sense.

Power Requirements and Energy Efficiency

Keeping refrigerated cargo at the right temperature requires constant power. Understanding energy consumption helps you plan routes better and control operating costs.

Energy Consumption Factors

Most refrigerated containers pull between 3 and 7 kilowatt-hours every hour they run. Hot weather? Expect those numbers to climb. Older units with worn-out insulation consume far more energy than newer models with modern thermal materials. Skip regular maintenance and watch your costs explode.

Dirty condenser coils reduce heat transfer efficiency. A worn door seal can let warm air in which causes the compressors to cycle more often. A solid preventive maintenance schedule can reduce fleet energy bills by 20% to 30%. Modern containers include smart controls that adjust cooling automatically based on conditions.

Generator Sets (Gensets)

Containers plug into ship electrical systems at sea and shore power at ports. Road transport creates a different challenge. You need independent power sources to maintain cooling during transit. Generator sets provide the solution.

These diesel engines mount onto truck chassis and generate electricity while moving. For long-haul trucking, reliable genset performance isn’t optional. Equipment failure means rising temperatures and potential cargo loss.

Key Selection Criteria Checklist

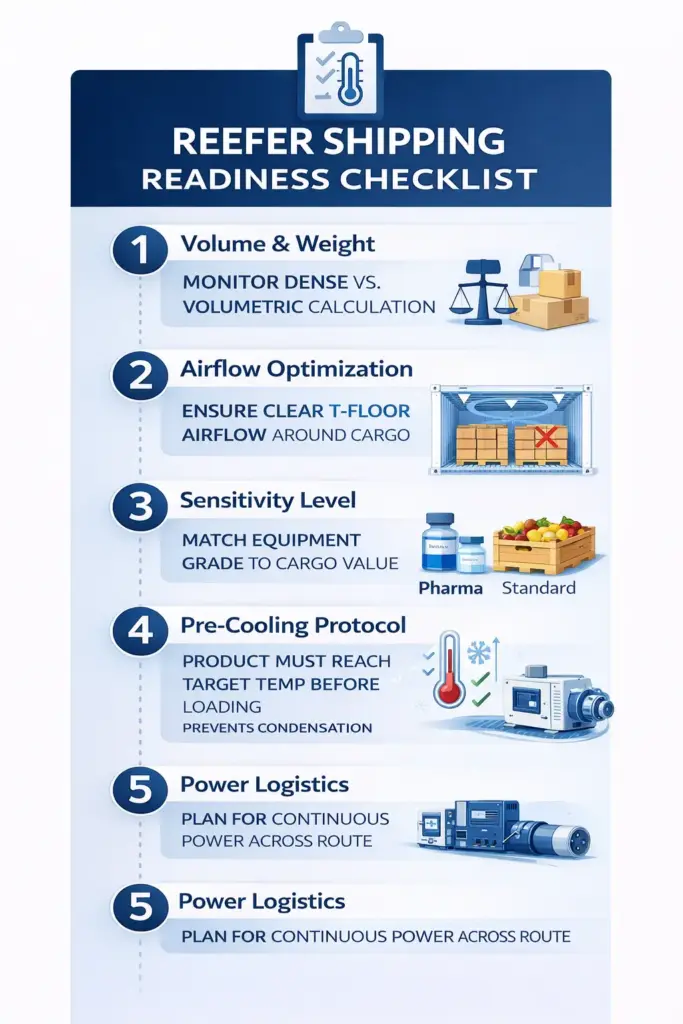

Use this checklist to match equipment to your actual shipping requirements:

1. Verify Cargo Volume and Weight

Calculate both volume and weight before booking. Dense products like frozen seafood max out weight limits before filling space. Lightweight items like fresh lettuce fill volumetric capacity before hitting weight restrictions.

2. Define Airflow Requirements

Packaging must allow cold air to reach the load’s center, not just circulate around edges. Most reefer containers push air upward through T-floor channels. Blocked channels cause the majority of produce damage claims.

3. Assess Temperature Sensitivity

Match equipment quality to cargo value and sensitivity. High-value pharmaceuticals require premium containers with comprehensive monitoring systems. Standard food products work fine in regular, well-maintained units.

4. Implement Pre-Cooling

Reefer containers maintain temperatures but can’t rapidly cool warm cargo. Always pre-cool products to target temperatures before loading. Loading warm goods causes frost formation and condensation issues.

5. Plan Power Availability

Verify reliable electricity at every route stop. Confirm voltage and plug compatibility at each location. Brief power interruptions during hot weather can cause rapid temperature excursions that damage sensitive cargo.

Conclusion

Selecting the right container balances size requirements, temperature specifications, and operational efficiency. Understanding unit size differences and verifying refrigerated container dimensions saves money while protecting cargo quality.

Proper humidity control and airflow management maintains product integrity throughout the supply chain. Equipment represents just one cold chain component. Loading procedures and transit monitoring matter equally. Your cargo’s arrival condition reflects planning decisions made at the shipment’s origin.

Ready to optimize your cold chain operations? For professional cold chain logistics expertise, consider partnering with Sea Trans Agencies for reliable freight forwarding solutions.