Ocean freight shipping moves over 90% of goods worldwide and forms the backbone of global trade. Selecting the appropriate container size reduces costs and improves supply chain efficiency. A 20-foot container measures approximately 20 feet in length, while a 40-foot container doubles this space.

Understanding these measurements of different types of containers helps businesses optimize shipping operations and minimize expenses. Making informed decisions about container selection directly impacts how efficiently your cargo moves across global routes.

Understanding Container Sizes in Feet and Basic Dimensions

Standard Container Size Specifications

Shipping containers are available in standard sizes that are measured in feet. The typical dimensions are 20 ft and 40 ft in length. For both sizes, 8 feet wide is average. Typical containers are 8 feet 6 inches tall, but High Cubes go up to 9 feet 6 inches. The international size shipping containers ensure that boxes and other items are positioned nicely and snugly on ships, trucks, and rail cars anywhere in the world.

Twenty-Foot Container Measurements

A 20-foot container has exterior dimensions of 19 feet 10.5 inches in length, 8 feet in width, and 8 feet 6 inches in height. The insides space of these containers are a bit smaller because of the steel walls. They are roughly 19 feet 4 inches in length, 7 feet 8.5 inches in width and stand at about 7 feet 10 inches high. This type of containers can capable of carrying up to about 47,840 pounds and has a cargo capacity of some 1,170 cubic feet.

Key specifications for 20 foot containers:

- Interior dimensions: 19′ 4″ long x 7′ 8.5″ wide x 7′ 10″ high

- Usable volume: 1,170 cubic feet

- Maximum payload: 47,840 pounds

Forty Foot Container Measurements

The 40-foot container measures 40 feet long, 8 feet wide, and 8 feet 6 inches high on the outside. Inside, it offers roughly 39 feet 5 inches in length. It maintains the same width and height as the 20-foot unit. This larger container provides approximately 2,385 cubic feet of storage volume and accommodates payloads up to 58,935 pounds. It is ideal for bulky, high-volume shipments.

Key specifications for 40-foot containers:

- Interior dimensions: 39′ 5″ long x 7′ 8.5″ wide x 7′ 10″ high

- Usable volume: 2,385 cubic feet

- Maximum payload: 58,935 pounds

Importance of Door Opening Dimensions

You must check door sizes before you load cargo. The door is often shorter than the ceiling inside. A normal door opening is 7 feet 8 inches wide and 7 feet 6 inches high. Big machines might fit inside but not through the door. Always make sure your cargo is smaller than the door opening.

Different Types of Feet and Container Design Standards

ISO Standards and International Compliance

Container design follows strict rules to keep cargo safe. ISO 668 is the main standard that sets container dimensions in feet and weight rules. These standards make containers work the same everywhere. The system uses feet and inches and each foot equals 12 inches. Knowing different types of feet measurements helps you plan cargo loads correctly.

Structural Standards and Safety Requirements

ISO standards also control how strong containers must be. These rules make sure any crane can lift a 20-foot or 40-foot container safely. The size rules are strict and its maximum allows only 0.25 inches difference. This makes containers stack safely on ships and lock onto trucks properly.

High Cube Containers and Extra Height Benefits

What Makes High Cube Containers Different

High cube containers give you extra height. A 40-foot high cube container is 40 feet long, 8 feet wide, and 9 feet 6 inches tall. This gives you 2,694 cubic feet of space. The extra 12 inches helps you pack tall cargo better.

Advantages of High Cube Container Selection

High cube containers hold more without needing extra boxes. You can stack more pallets tall or ship bigger equipment. This cuts down how many containers you need.

Benefits of high cube containers:

- More space: 309 cubic feet more than normal 40-foot boxes

- Same cost: Usually the same price as standard 40-foot boxes

- Faster work: Extra room helps workers load faster

- Safer: More space makes work safer

- Tall cargo: Fits items up to 8 feet 10 inches tall

Cost Efficiency of High Cube Design

High cube containers cost the same as normal 40-foot containers to ship. This makes them smart for big or tall cargo. The extra space can save you from needing a second container.

Evergreen Container Specifications and Modern Shipping Solutions

Understanding Evergreen Line Operations

Evergreen Line has some of the biggest container ships in the world. Their ships carry more than 20,000 TEU. Their evergreen container fleet follows ISO rules. They use normal and high cube containers.

Modern Container Design Excellence

Modern evergreen container design focuses on lasting long. These boxes use strong steel that fights rust from salt water. Strong floors handle heavy forklifts. Standard corner parts work with all cranes.

Global Fleet Standardization Benefits

Evergreen’s ships use special equipment that fits standard container dimensions in feet. The company keeps detailed information about cargo space and box weight. This helps you plan better and use space well.

Container Dimensions in Feet and Practical Cargo Calculations

Calculating Usable Volume Accurately

To pick the right container size in feet, you need to know usable space. A 20-foot container has about 1,170 cubic feet. A 40-foot container has about 2,385 cubic feet. Calculate your cargo by multiplying length times width times height of each box. Plan to use about 90% of the space. Perfect packing is hard to achieve.

Weight Versus Volume Considerations

Weight matters as much as space. A 20-foot container holds up to 47,840 pounds, while a 40-foot container holds up to 58,935 pounds. Always check that your cargo weight stays under these limits. Too much weight is dangerous and breaks the law.

Quick calculation steps:

- Change item sizes to cubic feet

- Add up all item volumes

- Compare total to container space

- Check total weight against limit

- Allow 10% loss for pallets and gaps

Selecting the Right Container for Your Cargo Type

Evaluating Cargo Characteristics

Your cargo type tells you which container to pick. Heavy things like machines, tiles, or metals need 20-foot containers. These hit the weight limit fast. Light things like furniture, clothes, or fabric need 40-foot containers. These fill the space before reaching weight limits.

Scheduling and Availability Factors

Think about timing when picking containers. Forty-foot containers are easier to find. They have faster booking and better schedules. Twenty-foot containers sometimes wait for matching shipments to pair up for rail transport.

Cost Analysis for Container Selection

A 20-foot container costs 75-90% of a 40-foot container price. But the cost per cubic foot is higher. Forty-foot containers give better value for big loads. You ship twice the cargo for a small price increase.

Space Constraints at Destination

Check if your delivery place has enough room. Small warehouses may need multiple 20-foot containers instead of one 40-foot box. Big trucks need wide turning space that some city locations don’t have.

Weight Distribution and Loading Best Practices

Understanding Loading Standards and Regulations

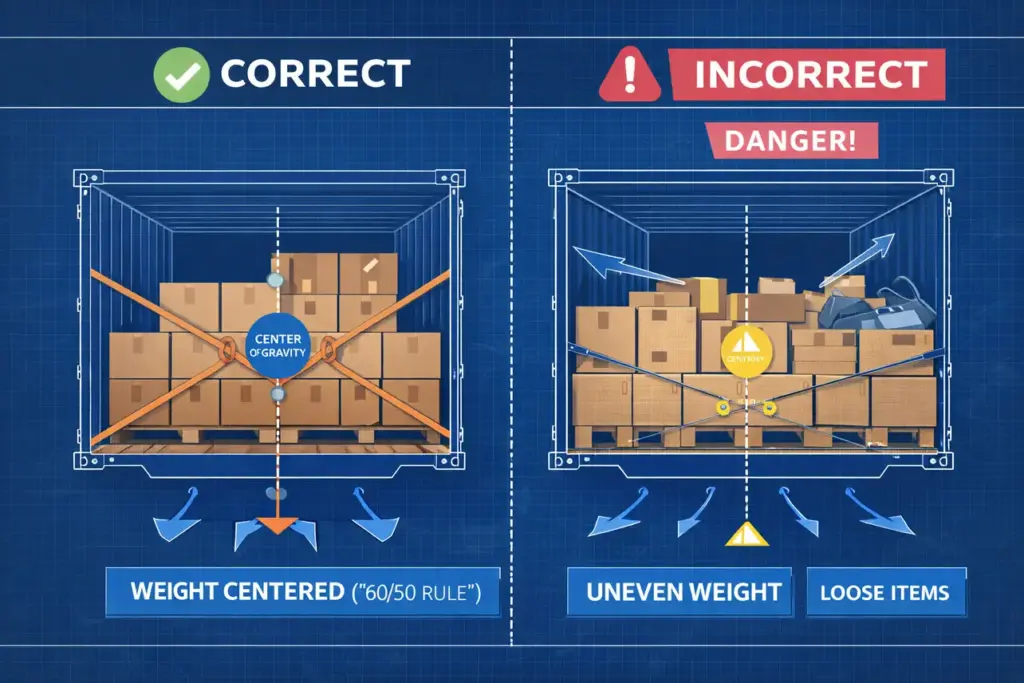

Proper weight spread keeps transport safe. Rules like the CTU Code give clear instructions. The main rule says 60% of cargo weight should sit over 50% of container length. This centers the load and stops accidents.

Practical Loading Techniques

Put heavy items on the bottom. Stack light items on top. Spread weight evenly across the floor width. Don’t pile heavy cargo on just one side. Use straps and blocks to hold cargo in place during the trip.

Main loading rules:

- Center weight: Keep 60% of weight in the middle

- Bottom first: Put heavy items on the floor

- Spread evenly: Use the full width

- Lock it down: Use straps and braces

Advanced Optimization Technologies

Special computer programs figure out the best packing plans. These tools think about sizes and weights. They can improve space use by 5% to 20%. This means you need fewer containers for the same cargo.

Cost Efficiency and Ocean Freight Economics

Understanding Container Pricing Models

Your container choice affects your shipping bill. A 40-foot container costs only 20% to 25% more than a 20-foot box but holds twice as much. This makes the bigger box the best value for large loads.

Less Than Container Load (LCL) Services

For small loads, use less than container load services. LCL puts cargo from many shippers into one shared box. This costs between $800 and $1,600 per shipment. It saves money when you can’t fill a whole 20-foot container.

Practical Strategies for Maximizing Container Efficiency

Standardizing Packaging and Dimensions

Make your packaging match pallet sizes. A 20-foot container holds 10 standard pallets. A 40-foot container holds 22 standard pallets. Boxes that fit perfectly on pallets waste less space.

Strategic Palletization Methods

Use pallets the smart way. Loose boxes waste space and break easier. Wrapped pallets stack nicely and load faster. Lined-up pallets use the full container width.

Packaging Redesign Opportunities

Think about changing your box sizes to stack better. Making boxes even a little bit smaller can help. This lets you stack higher and waste less space. Small changes add up to big savings.

Conclusion

Understanding container size in feet and different dimensions is the foundation of efficient logistics. Whether you choose 20-foot, 40-foot, or high cube containers, informed choices reduce costs and improve reliability. Calculate volumes accurately and distribute weight properly to ensure safety.

Ready to improve your shipping? Sea Trans Agencies has years of experience making shipping better. From picking containers to planning loads, our team gets results that help your business. If you want to hire professionals, you can trust Sea Trans Agencies for reliable service. Contact us today to start saving on your next shipment.