Managing stock is a hard task for businesses that trade across global borders. A scheduled LCL shipment is a great solution for this common logistics problem. LCL shipping lets you share a container with other companies to save space. You only pay for the exact space that your specific boxes take up.

This strategy helps you control your total international shipping costs significantly and effectively. In this guide, we will explain how scheduled LCL shipments optimize your stock. You will learn how to lower storage fees and improve your logistics process.

What is LCL Shipment and Why It Matters

Understanding LCL Shipment Meaning

The LCL shipment meaning refers to transport that does not fill a container. In LCL shipping, many shippers put their goods into one shared container space. We typically measure this specific type of cargo volume in cubic meters.

Your goods go to a container freight station for consolidation with other items. The ship takes the container to the final port for the deconsolidation process. This helps businesses that need to ship often without huge amounts of cargo.

What is LCL Shipment: Key Characteristics

An LCL shipment has several special features that you should understand clearly. Sharing space lowers your cost per cubic meter compared to paying for empty space. The process takes longer because workers need time to pack the shared container.

LCL gives you great flexibility because you can schedule shipments when you are ready. You do not have to wait until you have a full container available. This is perfect for businesses that have changing sales numbers throughout the year.

LCL Shipment Full Form and Components

The LCL shipment full form is known as Less than Container Load in logistics. An LCL shipment includes several different costs that you must pay to the carrier. Ocean freight is the price to move goods across the sea per CBM. Terminal handling charges are fees paid to workers who load the heavy container.

Documentation fees are paid for processing paperwork and necessary customs forms for entry. Consolidation fees pay for packing multiple shipments together into one single secure box. Fuel surcharges cover the variable cost of fuel for the ship during transit.

LCL Shipment Charges: Breaking Down the Costs

How LCL Shipment Charges Are Calculated

Companies calculate LCL shipment charges based on the total size of your cargo. They usually give you a price per cubic meter for your specific route. You can calculate your basic cost by measuring length, width, and height. Remember that total LCL shipment charges will be higher due to extra surcharges. You must add fees for handling, paperwork, and fuel to the final bill.

Origin and Destination Charges

You pay fees at the starting port which are known as origin charges. These charges typically make up about fifteen percent of the total shipping cost. They cover terminal handling and the processing of necessary customs forms for export. You also pay fees at the arrival port which are called destination charges. These fees cover customs clearance and the labor for unpacking the container. Sometimes prices go up during busy times which is called a peak surcharge.

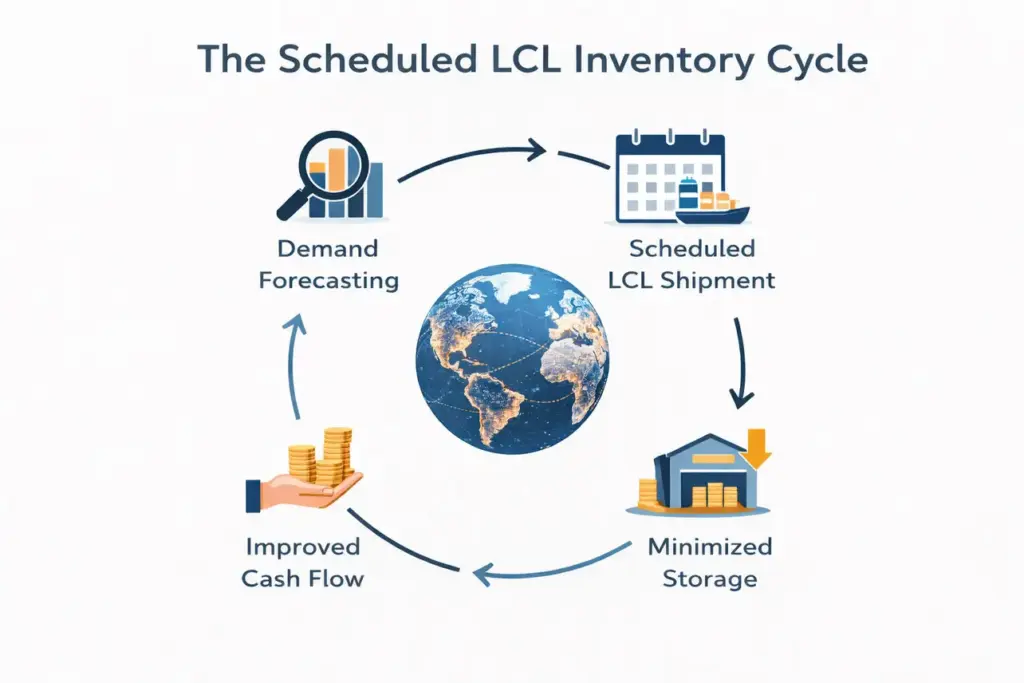

Optimizing Inventory Levels Using Scheduled LCL Shipments

Schedule Shipments According to Demand

You should schedule shipments based on what your customers actually buy from you. Do not just ship at random times without looking at your sales data. Plan smaller shipments when sales are slow to save money on shipping costs. Scheduled shipments help you avoid two big problems in your supply chain management. Too much stock costs money to store while no stock means lost sales. You should match your LCL shipments to your real needs for best results.

Reduce Storage Costs Through Frequent Shipments

Scheduled LCL shipments let you ship goods much more often than other methods. You do not have to wait months to fill a big container entirely. This strategy keeps less stock in your warehouse and lowers your storage bills. Frequent shipments also help your bank account by spreading out your cash flow. You spend smaller amounts over time which is easier for your business budget.

Use Just-in-Time Inventory Principles

Just-in-time is a smart way to manage stock for modern growing businesses. You get goods exactly when you need them which cuts down on waste. LCL shipments work well because you can schedule them to arrive on time. Talk to your suppliers and shipping agents about this efficient inventory strategy today. Pick a date that gets your goods to the warehouse right on time.

LCL and FCL Shipments: Understanding the Differences

When to Choose LCL Over FCL

You choose between LCL and FCL based on the total volume of cargo. LCL is usually cheaper if you have less than fifteen cubic meters total. For small loads like five cubic meters, LCL saves a lot of money. If you have more than fifteen cubic meters, FCL is often better choice. FCL is faster because the container does not stop to pick up goods. If you need goods very fast, you should probably choose the FCL option.

LCL and FCL Shipments: A Comparative Analysis

| Aspect | LCL Shipment | FCL Shipment |

| Volume Suitability | Good for cargo under 15 CBM | Good for cargo over 15 CBM |

| Cost per Unit | Higher per unit, but lower total bill | Lower per unit, but you rent the whole box |

| Transit Time | 28-35 days (takes longer to pack) | Faster, usually 5-9 days for the main trip |

| Flexibility | High – ship any time | Low – must wait to fill the box |

| Handling Risk | More handling means slightly more risk | Less handling, very secure |

| Storage Savings | High, because you ship often | Low, because you get too much stock at once |

Security and Damage Protection

FCL shipments are very secure because your container stays sealed the whole trip. LCL shipments get handled more because workers move your boxes to pack them. This adds a small risk of damage during the consolidation and deconsolidation process. Professional shippers pack things well to stop this damage from happening to cargo.

Practical Strategies for Scheduled LCL Shipment Planning

Implement Demand Forecasting

You need to guess your future sales correctly to optimize your shipping schedule. Use your past sales numbers to help you predict future customer order volumes. Work backward from the delivery date to pick the right shipment start date. Remember that LCL takes roughly thirty days so add time for customs checks.

Consolidate and Track Shipments

You can combine multiple orders into one single consolidated LCL shipment for efficiency. This saves you money and it is easier to track one single shipment. Choose a good shipping company that has experience with handling complex LCL shipments. Use the tracking tools your agent gives you to monitor your specific cargo. This information helps you prepare your warehouse team for the incoming inventory delivery.

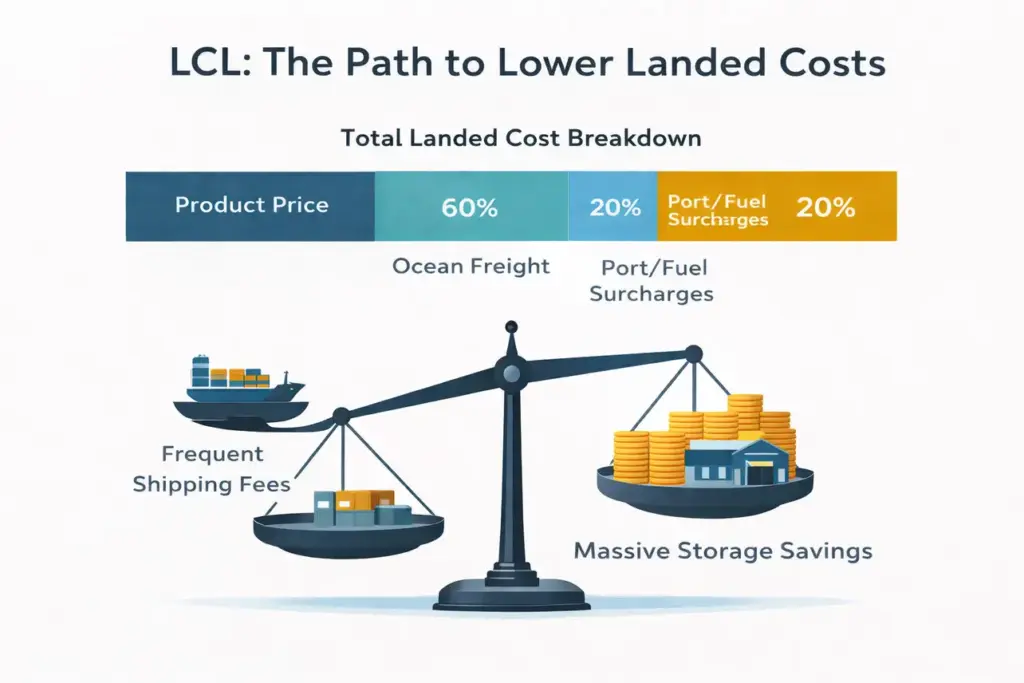

The Financial Impact of Optimized LCL Scheduling

Calculate Your Actual Landed Cost

You must know the true cost of your product to make good decisions. This is called the landed cost and it includes the price plus shipping. The total shipping cost is often fifty percent higher than ocean freight rates. You must add port fees and fuel surcharges to get the real cost.

Compare LCL Costs with Storage Savings

LCL shipments save you money on storage because you hold less inventory stock. Warehouses charge money for every box you store so less stock costs less. Often the money you save on storage is more than extra shipping fees. This savings pays for the extra handling fees of the LCL shipping method.

Best Practices for LCL Inventory Management

Review and Standardize

Check your stock numbers often to see which products are selling very quickly. If a product sells slowly you should ship it less often to save. Use the same box sizes for all your goods to save container space. This efficient packing lowers your CBM charges because you waste less empty space.

Communicate Clearly with All Partners

Talk to everyone involved in your supply chain to ensure smooth daily operations. Tell your suppliers when to have goods ready for the truck to pickup. Tell your warehouse manager when the truck will arrive at the delivery dock. Clear talk stops mistakes and delays from hurting your business and your profits.

Conclusion

Scheduled LCL shipments are a powerful tool for managing your global business inventory. You now know what is LCL shipment and how the charges work exactly. LCL is flexible because it lets you match your shipments to your sales. You can use LCL and FCL shipments together or just use LCL alone. The key to success is to schedule them well based on real data. Start using these tips today to lower your storage costs and improve cash flow.

If you want to hire professionals, you can trust Sea Trans Agencies for service. Our expert team knows how to optimize LCL shipments for your specific needs. We help businesses manage inventory efficiently to save time and reduce extra costs. Contact us today to learn how scheduled LCL shipments can help your supply chain.

Analyse this article, and give me 3 image suggestions. One of them should be Feature image and the rest of 2 are infographics for different sections.

Give me images suggestions like an image prompt. Keep in mind these images are related to the freight forwarding and shipping industry.