Peak season shipping creates a lot of stress for busy importers and exporters all over the world. Capacity constraints during major retail seasons often create bottlenecks that disrupt seamless business operations. These delays cost a lot of money and can hurt the good name of your business. They also reduce the profit you make at the end of the year.

If you understand why these delays happen during busy months, you can stop them. You can keep your shipments moving on time if you use smart plans before the peak season starts. This careful planning protects your money and keeps your customers happy all year long.

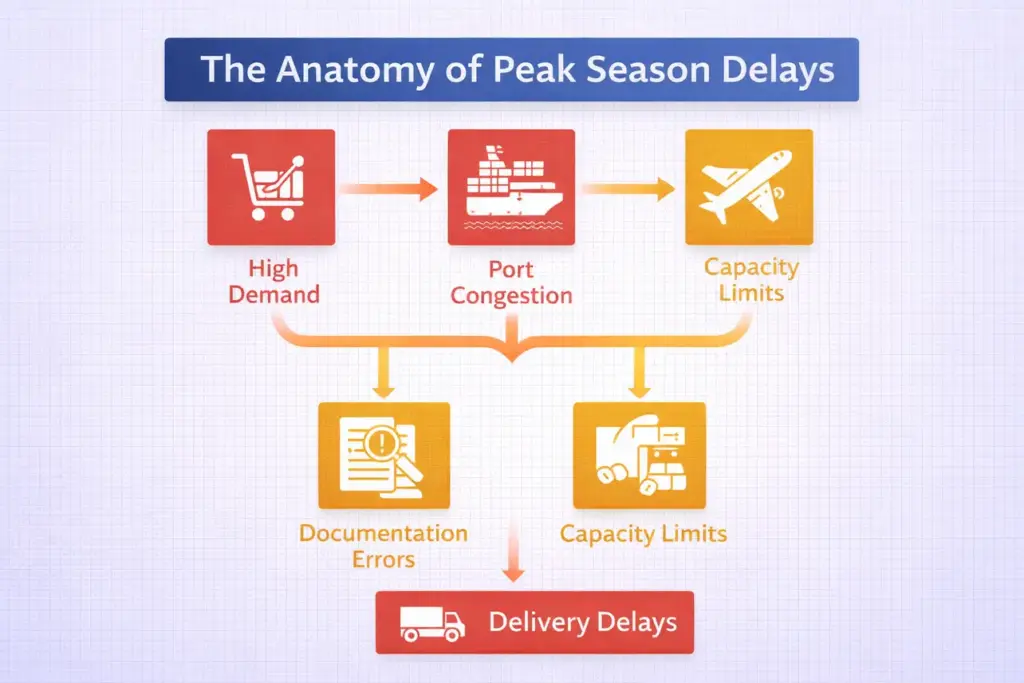

What Causes Freight Delays During Peak Seasons?

High Demand Strains Supply Chains

The amount of goods people ship often goes above what the supply chain can handle. Store owners and factories rush to buy products before big holidays and sales. This huge need for shipping creates a problem where there is too much cargo for the system.

Shipping companies often work with full ships and trucks during these intense times. Logistics companies have a hard time moving goods on time because they do not have enough trucks. Drivers must also follow strict rules about how many hours they can drive each day.

Port Congestion Blocks Movement

Major ports often become overcrowded in peak seasons. Thousands of containers pile up while waiting for unloading. A single large ship carries 20,000 containers and needs many workers to empty it.

Bad weather often makes port congestion worse. It also gets worse if workers go on strike and stop working. These problems create a chain of delays that pushes delivery dates weeks into the future. The problem is very bad at ports that do not have new machines or fast customs computers.

Documentation Errors Hold Shipments

Documentation mistakes are a leading cause of customs delays. Customs paperwork problems commonly slow down shipments in many regions. Customs officers will hold your goods to check them if you leave out important papers.

If you use the wrong codes or put the wrong labels on boxes, officers will inspect them. These inspections add many days to your wait time. These delays happen even after your goods have finished the long trip across the ocean.

Air Freight Delays From Booking Issues

Air freight is fast but faces limits in peak season. There is not enough space on planes during busy times, which causes booking problems. Air cargo space fills quickly without early booking.

Airlines always give space to customers who book their cargo weeks or months ahead. You will likely face air freight delays if you wait until the last minute. Mistakes with your papers can also make you lose the speed benefit of air travel.

Peak Season Timeline: When Delays Become Worst

You need to know when peak season happens to plan your shipments well. Importers must look ahead to these busy times and change their shipping schedules.

Traditional Peak Season Periods

- Late Summer to Fall (August-October): This time is the busiest for importers who ship goods to North America. Stores buy stock for school sales and then for big Christmas shopping events. Ports on the US West Coast handle the most shipments during these specific months.

- Winter Holidays (January-February): Factories in China close down completely for the long Chinese New Year holiday. Work starts slowly when people return from their holidays later in the month. Stores order new goods at the same time, which creates another huge demand for shipping.

Current Market Shifts

New tariffs caused some importers to ship earlier in 2025. Importers shipped goods early in May and June to avoid paying high taxes later. This caused traffic jams at big ports early in the year before it slowed down.

This early peak season shows that outside events can change the normal schedule. You should watch the news about trade rules to see changes in demand. This helps you fix your plan before problems start.

Prevention Strategy 1: Complete Documentation Before Shipment

The best way to stop delays is to do your paperwork right the first time. Missing or wrong papers cause more freight delays than any other common problem.

Make a full list of every document you need for the country you are shipping to. Your detailed list should include:

- Correct invoices that match the products and numbers in the box

- The right codes that describe your specific products

- Papers that prove where your goods were made

- Licenses that allow you to bring goods into the country

- Customs forms that show the true value of the goods

- Papers that show your goods are safe and follow rules

- Lists that describe exactly what is inside every package

Read about the rules of the destination country before you ship to avoid rejection. Every country has different rules for safety, labels, and the environment. Accurate paperwork greatly reduces customs delays.

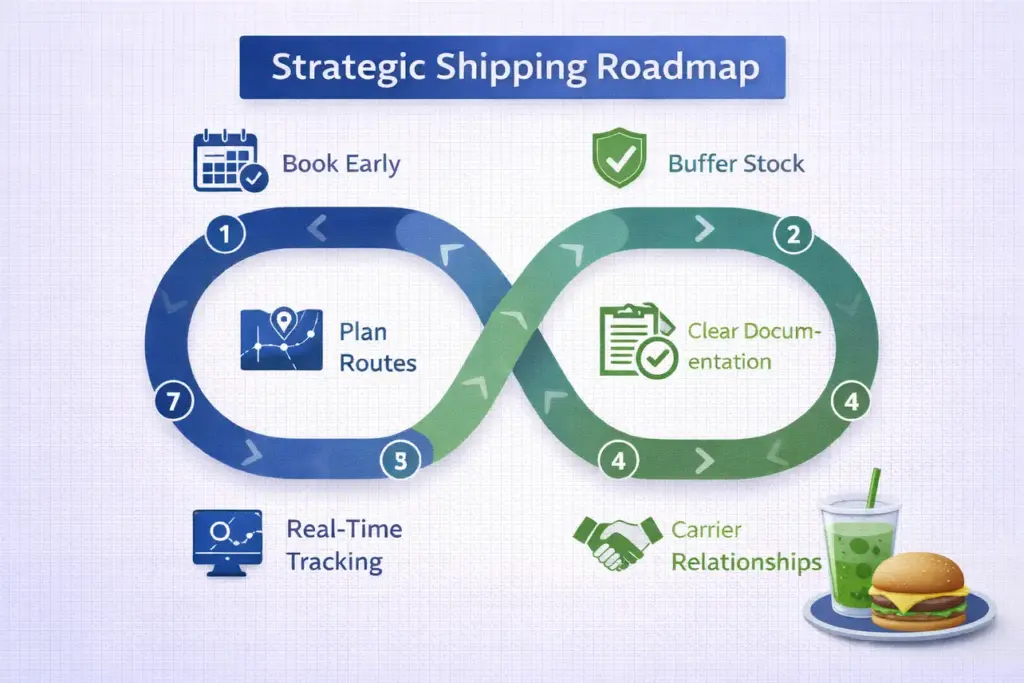

Prevention Strategy 2: Book Early and Secure Carrier Space

Booking early is your best defense against common shipping delays during peak season. If you book months in advance, you make sure there is space for your urgent goods.

During busy times, shipping companies help customers who booked their space early. If you book late, they might say no or charge you a lot of extra money. Air freight delays happen often because planes fill up very fast during these times.

When you book early, you get these clear benefits:

- You get a guaranteed spot on the ship or plane

- You pay normal prices instead of high peak season fees

- You have time to check your documents before you ship

- You have backup options if your first choice fails

- You get better routes and faster travel times

You should make backup plans part of your booking strategy to keep things moving. Find other routes and carriers in case your first choice is not available.

Prevention Strategy 3: Strengthen Carrier Relationships

The shipping partner you choose affects how reliable your deliveries are during peak season. If you build strong relationships with shipping companies, you get benefits during hard times.

Reliable partners provide:

- Faster service for their regular customers

- Early warnings about possible delays

- New routes when the normal ones are full

- Better prices because you ship with them often

- Help to find solutions when emergencies happen

Work with the same few partners for a long time instead of changing every time. These relationships lead to better service during busy periods. Check how well they work every few months to see if they are on time.

Prevention Strategy 4: Use Real-Time Tracking Systems

Seeing your shipment helps stop small delays from becoming big disasters for your business. Tracking systems show you where your cargo is during the whole trip.

Tracking tools provide:

- Live updates on where your shipment is

- Alerts if there is a delay or route change

- Checks on the temperature for sensitive goods

- Early signs that customs might hold your goods

- Proof to help you if you have an argument

If you have tracking data, you can make fast decisions when problems happen. You can find other solutions or tell customers the real arrival date right away. Digital platforms put information from many carriers in one place so you can see everything.

Prevention Strategy 5: Build Inventory Buffer Stock

Planning your stock protects you from uncertainty and unexpected problems in the supply chain. If you keep extra stock before peak season, you do not need expensive emergency shipments.

Plan your safety stock based on:

- How much product you sold in the past

- How long your suppliers take to make goods

- How reliable each shipping route is

- Changes in sales during different seasons

- Current rules about taxes and trade

It costs less to keep extra stock in a warehouse than to pay for emergency shipping. Safety stock also protects you from losing sales if a supplier is late. Use computer tools to guess your demand correctly and prevent running out of items.

Prevention Strategy 6: Diversify Shipping Routes and Carriers

If you rely on just one shipping company, you create a risk for your schedule. If that company has a problem, your whole shipping plan will fail immediately.

Using different carriers gives you:

- The freedom to pick the best company each day

- Safety when your main partner has problems

- Power to get better prices from companies

- Access to special services for certain goods

- Ability to reach customers in all areas

Send your goods to smaller ports to avoid long wait times and delays. Smaller ports often move shipments faster than big, crowded ports. You can also move cargo directly from one ship to another. This way avoids the traffic on land completely and stops typical ship delays.

Prevention Strategy 7: Choose Appropriate Shipping Methods

Choosing the right way to ship each product changes your risk of delay. Air freight and ocean freight have different costs and risks of delay.

Air Freight Advantages During Peak Season:

- The trip takes 1-7 days, which is much faster than ocean travel

- Schedules are very accurate with exact delivery times

- Customs processes are simpler with fewer delays

- It is better for goods that must arrive quickly

Ocean Freight Advantages:

- The cost is lower even with peak season fees

- It is cheaper for shipping large amounts of goods

- Ocean freight still offers better capacity

Use air freight for products that have tight deadlines or high storage costs. Use ocean freight for planned shipments that can arrive later to save money. During Chinese New Year, planes fill up weeks in advance. You must book three months ahead to get space for air cargo.

Prevention Strategy 8: Implement Technology Solutions

Digital tools help reduce the risk of delay by doing work automatically. These tools change your supply chain from fixing problems to preventing them.

Technology solutions that prevent delays include:

- Smart computer schedules that pick the best route

- Automated checks that find errors in papers

- Systems that connect to customs for fast clearance

- Tools that predict delays before they happen

- Dashboards that show all tracking data in one place

Sending digital papers to customs is faster than using physical paper forms. Digital payment systems for taxes also speed up the process for importers. Machines reduce human mistakes in order processing very effectively. Fewer human mistakes mean fewer delays caused by bad data entry.

Conclusion

Freight delays during peak seasons cost importers a lot of money in storage fees and lost sales. The good news is that you can prevent most of these delays. You can protect your shipments if you prepare your papers well and book space early.

Planning your stock and using different carriers makes your supply chain strong. These proven strategies work well for importers and exporters of all sizes. Your success depends on preparation that starts months before the peak season.

If you want to hire professionals, you can trust Sea Trans Agencies for reliable service. As the biggest logistic company in India and worldwide, they handle your cargo with unmatched expertise. They operate as the biggest cargo forwarder across any port of the world to ensure timely delivery.