Shipping costs reduce business profits when you send partial truckloads. Many companies waste money paying for empty truck space because they don’t have enough goods to fill an entire trailer. Freight consolidation solves this problem by combining multiple small shipments from different businesses into one complete load.

This approach allows you to share transportation expenses with other shippers while maintaining cargo safety. The method delivers measurable cost savings and improves shipping efficiency for businesses of all sizes. This guide explains how freight consolidation works and shows you practical ways to reduce your shipping expenses.

Understanding Consolidated Shipping and How It Works

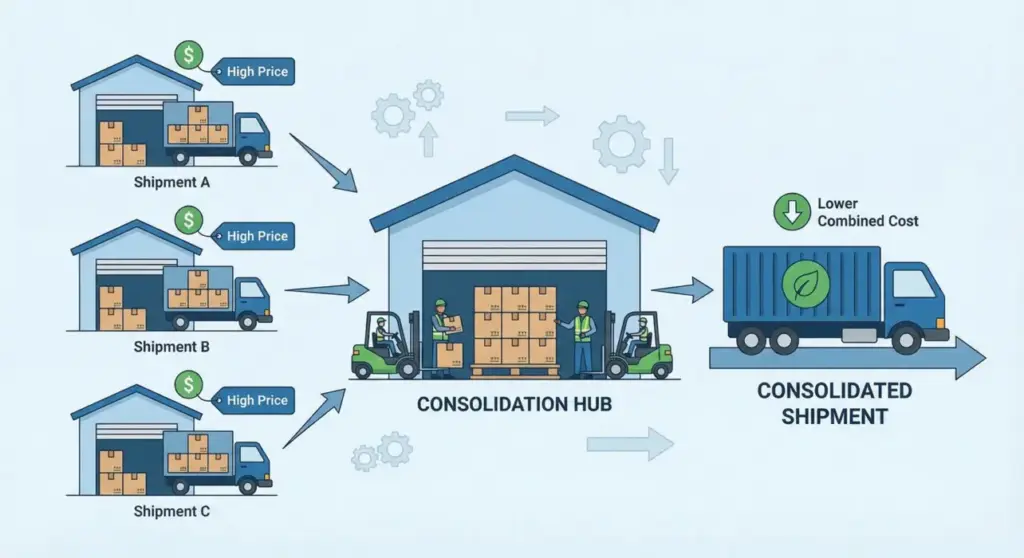

Sending small loads separately costs more because carriers charge minimum fees. Consolidated shipping puts several small shipments into one truck or container. You only pay for the space your cargo uses.

This method makes small shipment shipping cheaper by removing payments for unused space. Instead of three trucks going to the same area with partial loads, one full truck carries everything. This cuts the number of vehicles on the road and lowers costs for everyone.

The Step-by-Step Freight Consolidation Process

The process follows clear steps to ensure accuracy. It starts when a provider picks up your goods and takes them to a central consolidation warehouse.

Warehouse Consolidation: Sorting and Organizing Your Cargo

At the hub, workers organize cargo by destination. Warehouse consolidation uses organized procedures. Workers inspect, weigh, and measure each pallet to check size and condition. They make sure packaging is secure and paperwork matches the items. This stops errors that cause delays.

After checking everything, workers group your shipment with others going to the same place. Your cargo might wait a few days until they have enough volume to fill a truck. This waiting period keeps costs low.

Transportation Efficiency: From Hub to Final Destination

After grouping, the provider loads cargo onto a truck, plane, or ship. Transportation efficiency improves because the vehicle goes directly to the destination hub with fewer stops than regular LTL carriers. Fewer stops reduce travel time and fuel use.

At the destination, workers unload the container, separate individual orders, and arrange final delivery to each customer. This last step is usually quick, so goods arrive fast after the main trip.

Key Benefits for Small Businesses Using Consolidation

This shipping method offers real advantages that improve your supply chain performance.

Achieving Significant Cost Reduction in Logistics Operations

The main reason businesses use this method is to save money on transportation. Cost reduction logistics removes waste by cutting payments for empty truck space. When you share truck space, you also share fuel, driver, and maintenance costs with other shippers. This gives you much lower rates than booking a full truck or using regular parcel services for heavy items.

Enhanced Security and Protection for Your Shipments

Regular LTL shipping moves goods between many trucks at different terminals. Each transfer increases damage risk because of repeated handling. Consolidated shipments usually stay on the same vehicle from start to finish. Reduced handling decreases the chances of boxes getting damaged or lost. Your goods stay secure in their spot throughout most of the trip.

Environmental Benefits and Reduced Carbon Footprint

Today’s customers prefer eco-friendly companies that care about the environment. Filling one truck completely instead of running several half-empty trucks reduces carbon emissions significantly. This helps sustainability goals and reduces highway traffic.

Smart Packing Strategies for Better Shipping Rates

Good packing directly affects your rates because carriers charge based on space use. Less wasted space means lower costs for your shipments.

Essential Packing Tips for Small Shipment Shipping

Use standard pallets and make sure boxes fit squarely without hanging over edges. Overhanging items make the pallet wider and stop other cargo from sitting next to it. This wastes floor space and raises your freight charges.

Stackable pallets cost less to ship because they use vertical space well. If your goods can support weight on top, carriers can fit twice as much freight in the same space. Always mark whether your freight is stackable so warehouse teams can plan loads well and lower your costs.

Space Optimization Logistics for Maximum Container Utilization

For international shipments, space optimization logistics means filling containers to use both weight and volume capacity fully. If you have flexible deadlines, collect enough orders to fill more of a container yourself.

Or work with a consolidator who mixes dense, heavy cargo with light, bulky cargo. This mix reaches weight and volume limits at the same time, giving the best value for all shippers.

The Important Role of Freight Forwarding Services

Managing consolidation on your own is hard for most businesses. Professional freight forwarding services handle the complex details and provide access to established networks.

Gaining Access to Global Shipping Networks

Forwarders have relationships with carriers and warehouses in many countries and regions. They know which routes have enough volume to build consolidated loads easily. A single business might not have enough cargo to fill a container to one place, but a forwarder combines shipments from many clients to create workable cost reduction logistics solutions.

Expert Management of Documentation and Customs Compliance

Shipping goods to other countries needs accurate paperwork and proper compliance with rules. Forwarders manage bills of lading, packing lists, and customs forms for every item in the combined load.

They ensure that one shipper’s paperwork error doesn’t hold up the entire container. Their expertise keeps your shipment safe from compliance delays and fines caused by incorrect documents.

Comparing LTL and Consolidated Shipping Methods

People often confuse LTL (Less Than Truckload) with consolidation, but these are different services. LTL uses a hub-and-spoke system where freight travels through multiple terminals. The truck stops many times to pick up and drop off other shipments. This creates longer transit times and increases handling.

Consolidated shipping works more like a direct route. Once the load is complete, it goes straight to the destination area with few stops in between. It offers better security and more predictable delivery times than standard LTL because of fewer handling points.

However, LTL might be faster if you can’t wait for a consolidated load to gather enough volume. For small shipment shipping that isn’t time-sensitive, consolidation is usually the better choice for businesses watching costs.

When Should You Choose Freight Consolidation?

This method isn’t right for every situation. Think about your specific business needs and shipping requirements before deciding.

High-Frequency Shipments to Similar Destinations

If you ship to the same area regularly, this model gives consistent value. You can schedule production and order fulfillment to match the consolidator’s shipping schedule. This creates steady cargo flow and makes your supply chain more stable.

Non-Urgent Deliveries with Flexible Time Windows

Building a full consolidated load takes time to gather enough volume. If your customer needs the product within 24 hours, choose a dedicated courier or fast service. But if your delivery window is several days or weeks, the wait is worth the big savings. The small increase in delivery time pays off through significantly lower costs per shipment.

Overcoming Common Challenges in Consolidated Shipping

This shipping method has specific challenges that need planning.

Managing Coordination and Timing Expectations

The main challenge is schedule changes. Your cargo might sit in the warehouse for several days while the provider gathers other shipments going to the same place. This changing wait time makes it hard to promise exact delivery dates to customers. Clear talking with your logistics provider helps manage these expectations and gives realistic delivery windows.

Complexity in Warehouse Sorting and Distribution

At the receiving warehouse, workers must accurately sort many boxes from the consolidated load. Sorting mistakes can send your package to the wrong delivery route or place. Working with providers who use advanced warehouse consolidation technology lowers this risk. Barcode scanning and real-time tracking systems make sure every item goes to the correct delivery truck.

Best Practices for Successful Freight Consolidation

Plan your inventory needs well ahead to avoid emergency rush shipping that removes consolidation savings. Build strong relationships with reliable logistics partners who offer clear tracking and communication. Use space optimization logistics principles in your own facility to prepare goods properly before shipping. This reduces extra weight charges.

Always insure your cargo to protect against loss or damage. Even though consolidated shipping has less handling, accidents can still happen. Insurance saves your business from losing money. Also, review your shipping bills regularly. Check that the savings you expect from cost reduction logistics actually appear on your invoices.

Conclusion

Combining small shipments from multiple businesses helps you save money on shipping while keeping quality service. Freight consolidation cuts shipping costs, protects cargo better through reduced handling, and helps the environment.

This method gives small businesses the same shipping benefits that large companies get. You need to plan ahead and have flexible delivery times, but the money you save is real and substantial. This shipping solution grows with your company as you send more shipments.

Want to cut your shipping expenses? Sea Trans Agencies offers professional freight forwarding services that maximize savings through expert consolidation strategies. We handle warehouse operations, customs paperwork, and delivery tracking for you. Get a free shipping cost analysis from Sea Trans Agencies today and discover how much you can save on your next shipment.